We help you automate your processes,acquire data from field and bring thrm to your monitering.Control and analytics platforms.We also provide exploratory analytics tools to help to uncovered patterns in your data and gather insights to fine your production.

Our Capabilities

- Layout and 3D designs

- Automation Control panels

- PLC programming and HMI screens Development

- Industrial Robot programming

- SCADA Integration

- Analytical Engine platform

- End to End Deployment and Testing

- Labeling and Packaging Automation

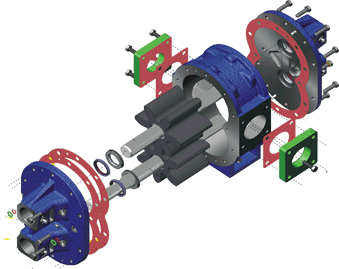

Layout and 3-D designs

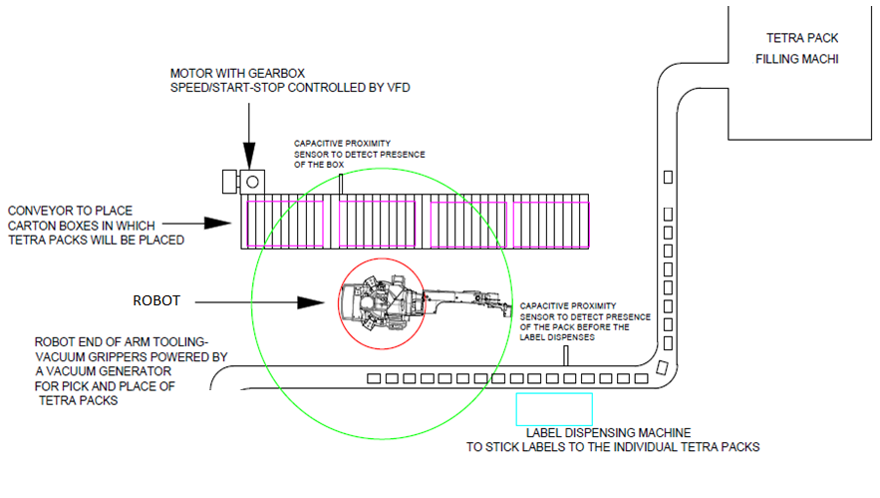

The layout of the robot cell and the Robot end of arm tooling are created with the latest CAD software.

Automation Control Panels

- The panels are designed and manufactured in-house as per the client’s requirements.

PLC Programming and HMI screens Development

- The industries depend on automating their entire lines using the PLC. Interactive HMI panels will enable operators to monitor the entire process.

The PLC offers the following advantages:-

- Rugged and designed to withstand vibrations, temperature, humidity, and noise.

- Have interfacing for inputs and outputs already inside the controllers.

- Very High Accuracy

- Low Power Consumption (Energy Saving)

- Economical & high Flexible

Industrial Robot Programming

- Our engineers are trained to program a variety of industrial robots for different applications such as material handling, welding, plasma cutting, dispensing etc.

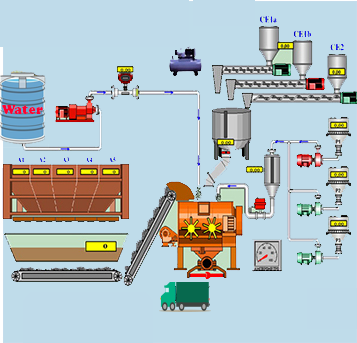

SCADA Integration

- Resources, such as people and plant assets, are optimized as SCADA promises high level control over the plant environment.

- Productivity is increased via analysis of processes used to improve plant and production efficiencies.

- Maintenance costs are reduced through centralized control and monitoring that minimize downtime.

- Quality is improved because the analysis of process data can result in preventing errors before they occur.

- Alarms are centrally managed which improves operational effectiveness by not overwhelming operators unnecessarily.

Analytical Engine Platform

- Data Acquisition (MODBUS, OPC-UA)

- Real Time Dashboards (Metrics, KPIs, Poka-Yoke)

- Exploratory Analytics from Time series data

- Anomaly Detection, Prediction and Prescription

- Improve Operation Efficiency

- Energy Utilization & Optimization

- Uptime of Asset

- Decision Making in Real-time

End to End Deployment and Testing

- Our expertise lies in automating production lines and ensuring all aspects are thoroughly tested.

Labeling and Packaging Automation

Operations:

- Weighing

- Leak detection

- Labelling

- Packaging

Skills:

- Layout and 3D designs

- PLC programming/

- HMI screens Development

- Robot Programming

- Electrical & Pneumatic panel Design

- End to End Deployment and Testing